Technology & Solutions

EDI (CEDI) SYSTEM – THE OPTIMAL CHOICE FOR ULTRAPURE WATER TREATMENT SOLUTIONS

Xem nhanh

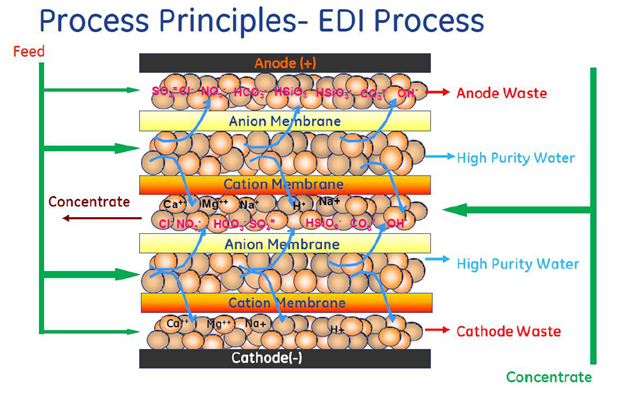

EDI (Electrodeionization) or CEDI (Continuous Electrodeionization) is an ideal solution for producing ultrapure water thanks to its continuous operation, chemical-free process, low operating costs, and stable water quality. This technology is increasingly favored in industries that require extremely high water purity standards such as electronics, pharmaceuticals, food & beverage, laboratories, and more—where water quality plays a critical role in accuracy and reliability.

WASOL A PIONEER IN EDI (CEDI) SYSTEM DESIGN AND CONSTRUCTION IN VIETNAM

WASOL is proud to be a pioneer in the design and implementation of EDI (CEDI) systems in Vietnam. By combining cutting-edge technology with extensive practical experience, we deliver high-performance, stable-operating EDI systems tailored to meet diverse customer needs.

Our highly experienced engineering team, professional execution process, and comprehensive EPC capabilities are the foundation that has made WASOL the preferred partner for ultrapure water treatment projects nationwide.

EDI (CEDI) systems are extensively used in industries that demand ultrapure water, where the output water quality must maintain extremely low and stable conductivity. Key application sectors include:

-

Electronics & Semiconductors

-

Pharmaceuticals & Healthcare

-

Food & Beverage Industry

-

Chemical Manufacturing

-

Laboratories & Research Facilities

KEY ADVANTAGES OF EDI OVER TRADITIONAL MIXED BED ION EXCHANGE SYSTEMS

1. High Purification Efficiency

EDI systems can achieve purification rates up to 99%, effectively removing nearly all remaining ions from water. This results in very high water purity, suitable for critical applications. The system also supports large flow rates with a compact footprint.

2. No Chemical Regeneration Required

Unlike conventional ion exchange systems that require acids and caustic soda for resin regeneration, EDI uses electricity for continuous in-place resin regeneration. This enhances safety, cleanliness, and environmental friendliness.

3. Continuous Operation

EDI systems operate continuously without downtime for regeneration, ensuring uninterrupted water quality and minimizing system downtime.

4. High and Consistent Water Quality Output

EDI can produce water with resistivity up to 18 MΩ·cm, meeting stringent quality requirements in industries such as pharmaceuticals, electronics, and microchip manufacturing.

5. Optimized Long-Term Operating Costs

Although EDI may require higher initial investment compared to traditional ion exchange systems, it significantly reduces chemical, wastewater treatment, labor, and downtime costs, providing excellent long-term cost efficiency.

6. Highly Automated and Easily Integrated

EDI is easily integrated into modern RO-UPW systems and can be managed via SCADA or PLC-based automation systems for streamlined control and monitoring.

WHY CHOOSE WASOL AS YOUR EPC CONTRACTOR FOR EDI (CEDI) SYSTEMS?

Wasol not only delivers compliant EDI solutions, but also tailors each system to match your plant’s real-world conditions—including feed water quality, installation space, and automation requirements.

With flexible design capabilities and in-house fabrication and assembly, Wasol ensures shorter lead times and strict quality control from start to finish.

Our EDI (CEDI) systems are designed for:

-

High reliability

-

Easy operation and maintenance

-

Energy efficiency

-

Long-term performance and ROI

Wasol supports customers throughout the entire project lifecycle:

-

Technology consulting

-

System design and installation

-

Operator training and after-sales support

We use premium EDI components from the world’s leading brands to ensure stability and system longevity.

Our fast response time, professional implementation process, and dedicated technical team guarantee peace of mind for our clients during system operation.

CONTACT WASOL – EPC CONTRACTOR FOR EDI (CEDI) SYSTEMS

If you’re looking for a reputable and professional EPC contractor to design and install your EDI (CEDI) system, Wasol is your trusted partner. Let us help you with what we do best.

For more information, please contact us via the following channels:

Hotline: +84 90 668 8934 – (028) 3961 0884

Email: info@wasol-vn.com

Website: wasol-vn.com

Office Address:

57/14-16 To Hieu Street, Phu Thanh Ward, Ho Chi Minh City, Vietnam

TIẾNG VIỆT

TIẾNG VIỆT