Technology & Solutions

WASOL – LEADING PARTNER IN DESIGNING AND CONSTRUCTING WASTEWATER RECYCLING SYSTEMS WITH MLD (MINIMUM LIQUID DISCHARGE) & ZLD (ZERO LIQUID DISCHARGE) TECHNOLOGIES

Xem nhanh

MODERN WASTEWATER TREATMENT TRENDS: MLD & ZLD – OPTIMAL SOLUTIONS FOR SUSTAINABLE DEVELOPMENT

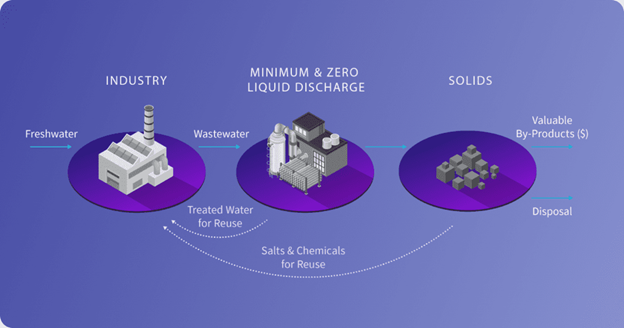

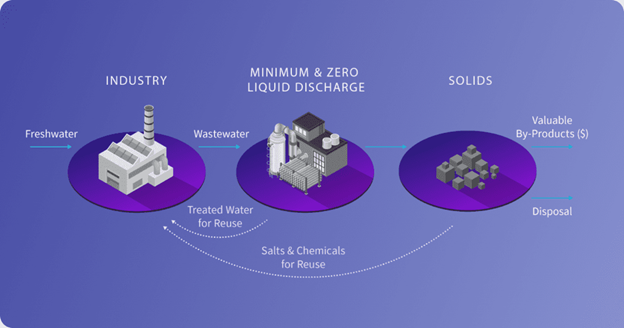

Amid increasing pressure from environmental regulations and the need to conserve water resources, many industrial enterprises are turning to advanced wastewater recycling and reuse models such as MLD (Minimum Liquid Discharge) and ZLD (Zero Liquid Discharge). These cutting-edge treatment technologies maximize the recovery of clean water streams while minimizing or completely eliminating wastewater discharge into the environment.

Implementing MLD wastewater reuse systems or ZLD treatment and recycling systems not only helps businesses comply with regulations but also delivers significant benefits in operational cost savings, brand reputation, and long-term sustainability across the supply chain.

WASOL – A PIONEER IN IMPLEMENTING MLD & ZLD WASTEWATER TREATMENT AND RECYCLING SYSTEMS IN VIETNAM

With over a decade of expertise in water and wastewater treatment, WASOL is currently a leading EPC contractor in Vietnam, providing advanced wastewater reuse solutions—especially MLD (Minimum Liquid Discharge) and ZLD (Zero Liquid Discharge) systems.

WASOL offers a comprehensive turnkey solution:

-

Surveying, analyzing, and evaluating wastewater quality

-

Custom-designed MLD/ZLD systems tailored to each industry and reuse requirement

-

Equipment supply, construction, installation, commissioning, and handover

-

Operator training, warranty, and post-project technical support

WHAT ARE MLD AND ZLD – MODERN WASTEWATER TREATMENT SOLUTIONS?

MLD – Minimum Liquid Discharge

MLD (Minimum Liquid Discharge) is a modern wastewater treatment technology that significantly reduces wastewater discharge while allowing most of the treated water to be reused. Depending on the feedwater characteristics and applied technology, MLD systems typically achieve 50–90% water recovery.

ZLD – Zero Liquid Discharge

ZLD (Zero Liquid Discharge) is a more advanced treatment technology aimed at eliminating all wastewater discharge to the environment (100% zero liquid waste). In ZLD systems, all wastewater is treated, reused, or transformed into solid waste through processes such as reverse osmosis (RO), evaporation, and crystallization.

WHY SHOULD BUSINESSES INVEST IN MLD OR ZLD WASTEWATER TREATMENT TECHNOLOGIES?

As environmental regulations grow increasingly stringent and water resources become scarcer, adopting advanced wastewater reuse technologies such as MLD (Minimal Liquid Discharge) or ZLD (Zero Liquid Discharge) is not merely a technical solution—it is a sustainable development strategy for businesses.

Specifically, both of these wastewater recycling technologies help businesses:

-

Optimize water resources by recovering and reusing treated water

-

Ensure compliance with environmental regulations

-

Reduce long-term operating costs by minimizing freshwater intake and wastewater discharge

-

Enhance corporate image and credibility, especially with international customers, partners, and investors

-

Mitigate environmental risks, protecting surrounding communities and ecosystems near production sites

MLD VS. ZLD – WHICH SOLUTION IS RIGHT FOR YOUR PLANT?

Choosing between MLD (Minimal Liquid Discharge) and ZLD (Zero Liquid Discharge) technologies depends on several factors, including: the industry type, wastewater contamination level, legal requirements, investment budget, and the plant’s specific reuse goals.

Below is a comparison table to help businesses better evaluate their options:

| Criteria |

MDL (Minimum Liquid Discharge) |

ZLD

(Zero Liquid Discharge) |

| Objective | Minimize the volume of wastewater discharged into the environment | Completely eliminate liquid waste discharge |

| Water Recovery Rate | 50–90%, depending on technology and influent quality | Nearly 100% of wastewater is reused |

| Output Composition | Recycled clean water + a portion of concentrated wastewater | Recycled clean water + solid concentrate (salts, sludge) |

| Capital Investment | Medium – lower than ZLD | High – requires evaporators, crystallizers, and sludge treatment systems |

| Operating Costs | Medium – lower than ZLD | High – significant energy, chemical consumption, and maintenance costs |

| System Complexity | Moderate – easy to operate and scalable | High – requires specialized technical teams and strict operational protocols |

| Environmental Sustainability | Reduces environmental burden, enables efficient water reuse | Fully green, aligned with ESG strategies and sustainable development goals |

TECHNOLOGIES APPLIED IN MLD & ZLD WASTEWATER TREATMENT SYSTEMS

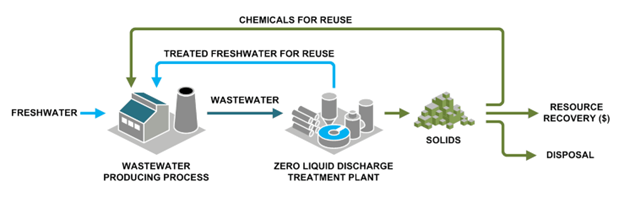

MLD (Minimum Liquid Discharge) and ZLD (Zero Liquid Discharge) are complex wastewater treatment and recycling processes that involve multiple stages and the integration of various technologies. The selection of specific technologies depends on the composition of the wastewater and the operating conditions of the system. The treatment process typically includes the following stages:

1. Pretreatment:

The initial stage is designed to remove large particles, suspended solids (TSS), hardness, and other elements that may interfere with downstream equipment. This step helps maximize system performance and longevity. Common technologies used include: coagulation, flocculation, sedimentation, MMF, DMF, GAC, UF, etc.

2. Concentration:

After pretreatment, the water stream is separated into two parts: reusable clean water and concentrated wastewater containing high salt content. Typical technologies at this stage include NF membranes, RO, and EDR systems. Most MLD systems end at this stage, with a water recovery rate of 50–90%.

3. Evaporation & Crystallization (specific to ZLD):

For ZLD systems, the remaining concentrated wastewater undergoes evaporation and crystallization to eliminate all liquid discharge, leaving only dry solids. The water recovered from evaporation is reused. While this stage offers high treatment efficiency, it requires substantial capital and operating costs, making ZLD suitable for industries with strict discharge standards.

WASOL – A TRUSTED EPC CONTRACTOR FOR MLD & ZLD WASTEWATER TREATMENT SYSTEMS

With nearly 15 years of experience in the water and wastewater treatment sector, WASOL has established itself as a leading EPC contractor in Vietnam, specializing in the design and construction of advanced MLD and ZLD systems for key industrial sectors.

WASOL provides a comprehensive, end-to-end solution, including: site survey – technology consultation – engineering design – equipment supply – construction and installation – commissioning and handover. Each system is optimized to meet criteria such as cost-efficiency, high treatment performance, easy maintenance, and strict compliance with current environmental regulations.

More than just a contractor, WASOL is a trusted technology and engineering partner to many domestic and international corporations. Notably, WASOL partners with Veolia, the world leader in water resource management. This strategic collaboration allows WASOL to rapidly access cutting-edge technologies while ensuring superior quality in every project.

WASOL is committed to accompanying businesses on the journey toward circular, eco-friendly production models—enhancing brand reputation and boosting competitiveness in an increasingly sustainability-driven marketplace.

CONTACT WASOL – CONSULTING FOR MLD & ZLD WASTEWATER SOLUTIONS

If you are looking for a professional contractor to design and build a complete MLD or ZLD wastewater recycling system, WASOL is your trusted choice. Let us help you with what we do best. For more information, please contact us via the following channels:

-

Hotline: 090 668 8934 – 0283 961 0884

-

Email: info@wasol-vn.com

-

Website: wasol-vn.com

-

Office Address: 57/14-16 Tô Hiệu Street, Phú Thạnh Ward, Ho Chi Minh City, Vietnam

TIẾNG VIỆT

TIẾNG VIỆT