What Is a Boiler System?

A boiler system is a device that uses fuel to heat water or generate steam for industrial and domestic applications. It plays a vital role in various industries such as food processing, textiles, chemicals, and energy production.

Types of Boiler Systems

Boiler systems come in many types, classified based on structure, fuel used, application, and heat transfer method. The most common types include:

-

Industrial boiler

-

Domestic boiler

-

Water tube boiler

-

Fire tube boiler

-

Fluidized bed boiler

-

Chain grate boiler

-

Coal-fired boiler

-

Oil/Gas-fired boiler

-

Biomass boiler

-

Electric boiler

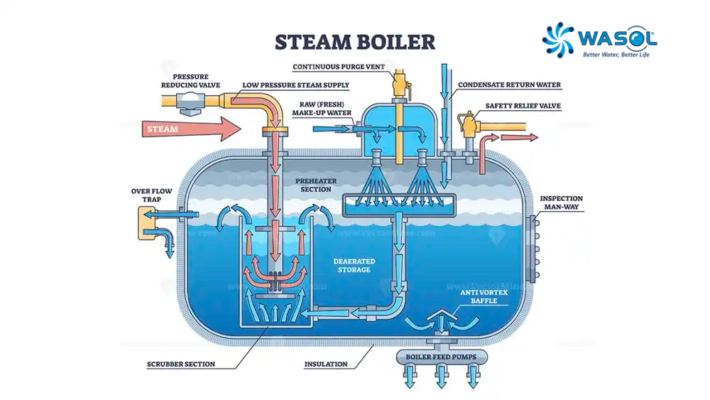

Main Components and Accessories of a Boiler System

A boiler system consists of various components and accessories to ensure efficient, safe, and energy-saving operation. Key parts include:

Combustion Chamber

-

Where the fuel is burned to generate heat.

-

Can use coal, oil, gas, biomass, or electricity.

-

Includes types such as chain grate, fluidized bed, and burner-type chambers.

Steam Drum

-

The main section where water is stored and steam is generated.

-

Designed to withstand high pressure and made of heat-resistant steel.

-

Often equipped with one or more insulation layers to retain heat.

Heat Exchanger Tubes

-

Where heat is transferred from hot gases to water to generate steam.

-

Two main configurations:

-

Fire tube boiler: Hot gases pass through tubes surrounded by water.

-

Water tube boiler: Water flows inside tubes surrounded by hot gases.

-

Superheater

-

Increases the temperature of the steam beyond saturation point.

-

Enhances efficiency and reduces energy loss.

Economizer

-

Utilizes waste heat to preheat feedwater before entering the boiler.

-

Saves fuel and improves system efficiency.

Pressure Reducer

-

Monitors and automatically adjusts the pressure inside the boiler.

Safety Valve

-

Releases excess pressure when it exceeds safe limits.

-

Prevents boiler explosions due to overpressure.

Blowdown Valve

-

Removes accumulated sludge and impurities at the bottom of the boiler to prevent scaling.

Feedwater Pump

-

Supplies water to the boiler to maintain pressure and continuous steam generation.

-

Typically uses centrifugal or piston pumps.

Water Treatment System

-

Eliminates impurities from the water to prevent scaling and corrosion.

-

May include sediment filtration, demineralization, and oxygen/CO₂ removal.

Working Principle of a Boiler System

The boiler system operates on the principle of converting thermal energy from fuel into steam or hot water, involving the following key steps:

-

Fuel combustion: Burns coal, oil, gas, or biomass to generate heat.

-

Heat transfer: The heat is transferred to water within the system.

-

Steam or hot water generation: High-pressure steam or hot water is produced for specific uses.

-

Heat recovery and circulation: Water may be recirculated to improve energy efficiency.

Applications of Boiler Systems

-

Food factories: Use steam for food processing and product sterilization.

-

Textile industry: Supply steam for dyeing and industrial laundry processes.

-

Chemical production: Used in distillation and chemical synthesis processes.

-

Power plants: Generate steam to drive turbines for electricity production.

-

Heating systems: Used in large buildings, hotels, and hospitals.

Benefits of Using Boiler Systems

-

High efficiency: Maximize fuel energy utilization.

-

Cost saving: Reduce fuel waste and optimize operation.

-

Fuel flexibility: Can use coal, oil, gas, electricity, or biomass.

-

Environmental protection: Many modern boilers reduce CO₂ and toxic emissions.

-

High safety: Modern systems are equipped with sensors and safety valves.

Considerations When Choosing a Boiler System

-

Appropriate capacity: Ensure it meets production demand.

-

Fuel type: Select boilers compatible with available fuel sources.

-

Energy consumption: Prioritize energy-efficient systems.

-

Investment and maintenance costs: Consider budget and maintainability.

-

Safety standards: Ensure the system meets international safety standards.

Boiler System Maintenance for Optimal Performance

-

Periodically inspect components such as the boiler, pipelines, and safety valves.

-

Clean heat exchange surfaces to prevent scaling.

-

Check the combustion system to ensure high efficiency.

-

Monitor pressure and temperature for safe operation.

-

Use water treatment chemicals to prevent scaling and corrosion.

Wasol – EPC Contractor for Boiler System Consulting, Design, and Construction

Wasol is a leading EPC contractor specializing in providing boiler system solutions for various industries. With over 10 years of experience, Wasol delivers modern, energy-efficient, and environmentally friendly boiler systems that meet international standards.

Wasol’s EPC Services for Boiler Systems

System Design

-

Analyze needs and optimize the appropriate boiler solution.

-

Integrate energy-saving technologies to reduce operational costs.

-

Ensure compliance with safety and environmental standards.

Equipment Supply

-

Partner with reputable boiler brands.

-

Provide genuine, high-performance equipment.

-

Fully equipped with synchronized components and accessories.

Construction and Installation

-

Experienced team of engineers.

-

Installation meets international standards and ensures safety.

-

Optimize space and operational efficiency.

Maintenance and Servicing

-

Periodic inspection and heat exchanger cleaning.

-

Use of water treatment chemicals to prevent scaling.

-

Prompt technical support to reduce downtime.

Benefits of Choosing Wasol as Your EPC Contractor for Boiler Systems

-

Comprehensive solutions: Full-package service from design, supply, installation to maintenance.

-

Cost-effective: Advanced technology application reduces fuel consumption.

-

Guaranteed quality: Genuine equipment with long-term warranty.

-

Safe and sustainable: Meet environmental and occupational safety standards.

Applications of Wasol Boiler Systems

-

Food factories: Provide steam for processing and sterilization.

-

Textile industry: Supply heat for washing and dyeing processes.

-

Power plants: Generate steam to rotate turbines and produce electricity.

-

Industrial heating: Used in hotels, hospitals, and large buildings.

Contact Wasol for Boiler System Consultation

WASOL CORP

Address: 57/14-16 To Hieu Street, Phu Thanh Ward, Ho Chi Minh City, Vietnam

Phone: 0283 961 0884 – 090 668 8934

Email: info@wasol-vn.com

Website: wasol-vn.com

Reviews

There are no reviews yet.

Related products

Water Treatment System

Water Treatment System

Installation and Maintenance of Chiller Systems for Businesses

TIẾNG VIỆT

TIẾNG VIỆT

Be the first to review “Installation of Energy-Efficient Boiler System for Factory”